Customer Projects

Our customers value the quality of our work just as much as our integrity and discretion

– we can therefore share only minimal details about our current projects.

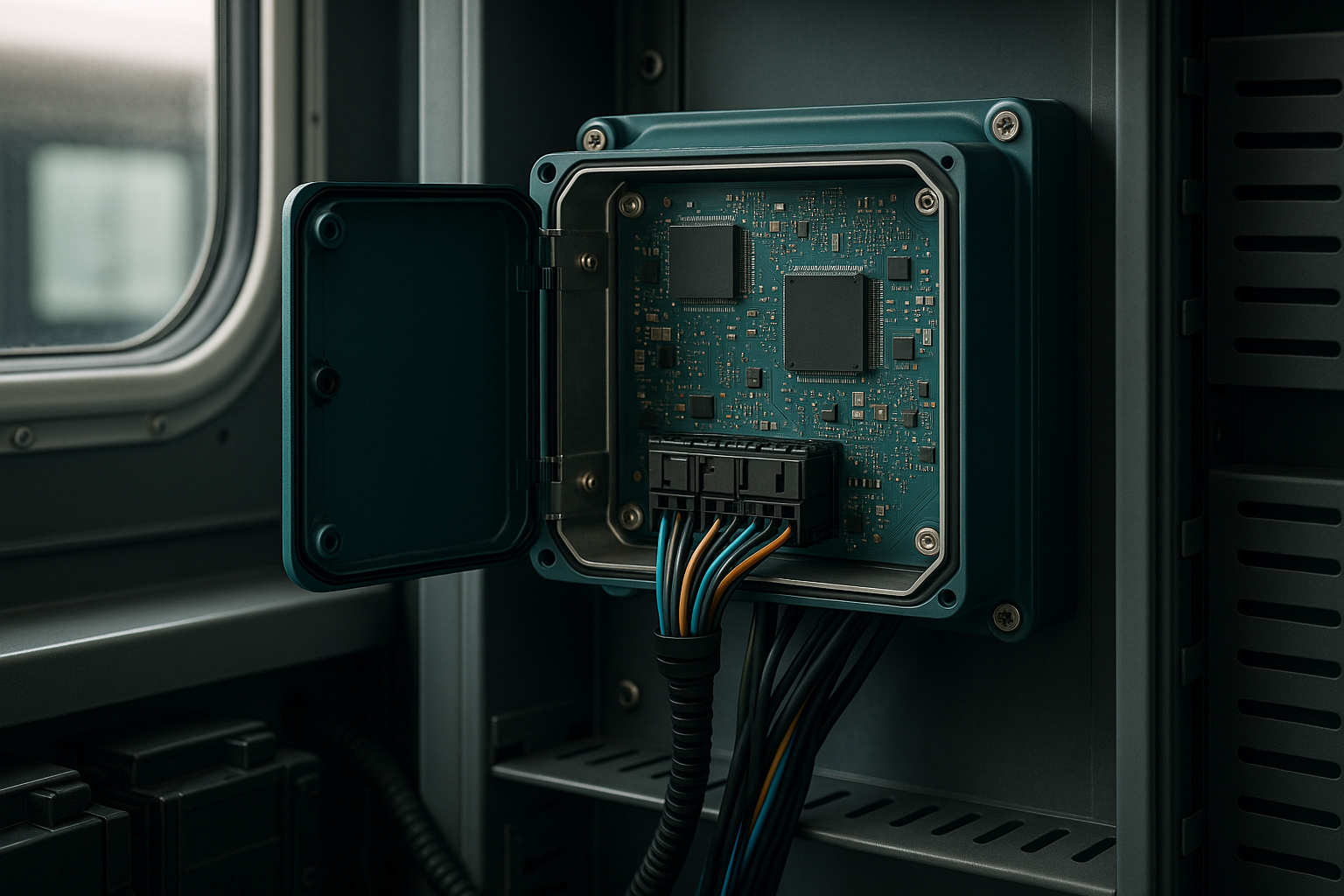

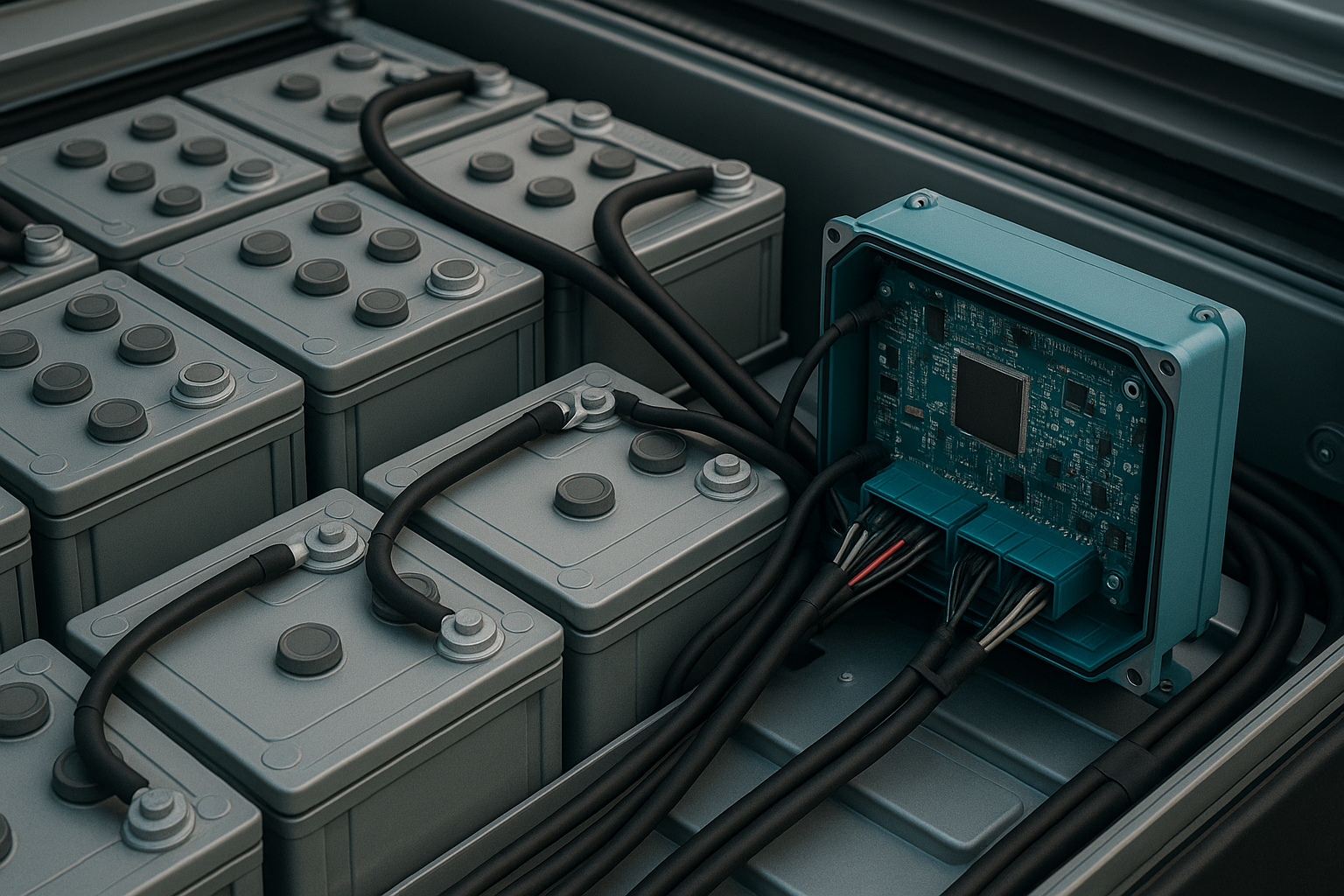

We supported Würth Elektronik ICS GmbH in the development of the first SIL2 (EN 61508) certified Battery Management System for industry storages in Europe. The tight cooperation of the internal WE ICS team and ourselves led to the full implementation of all functions of the ISO62619 and a successful assessment by TÜV Nord.

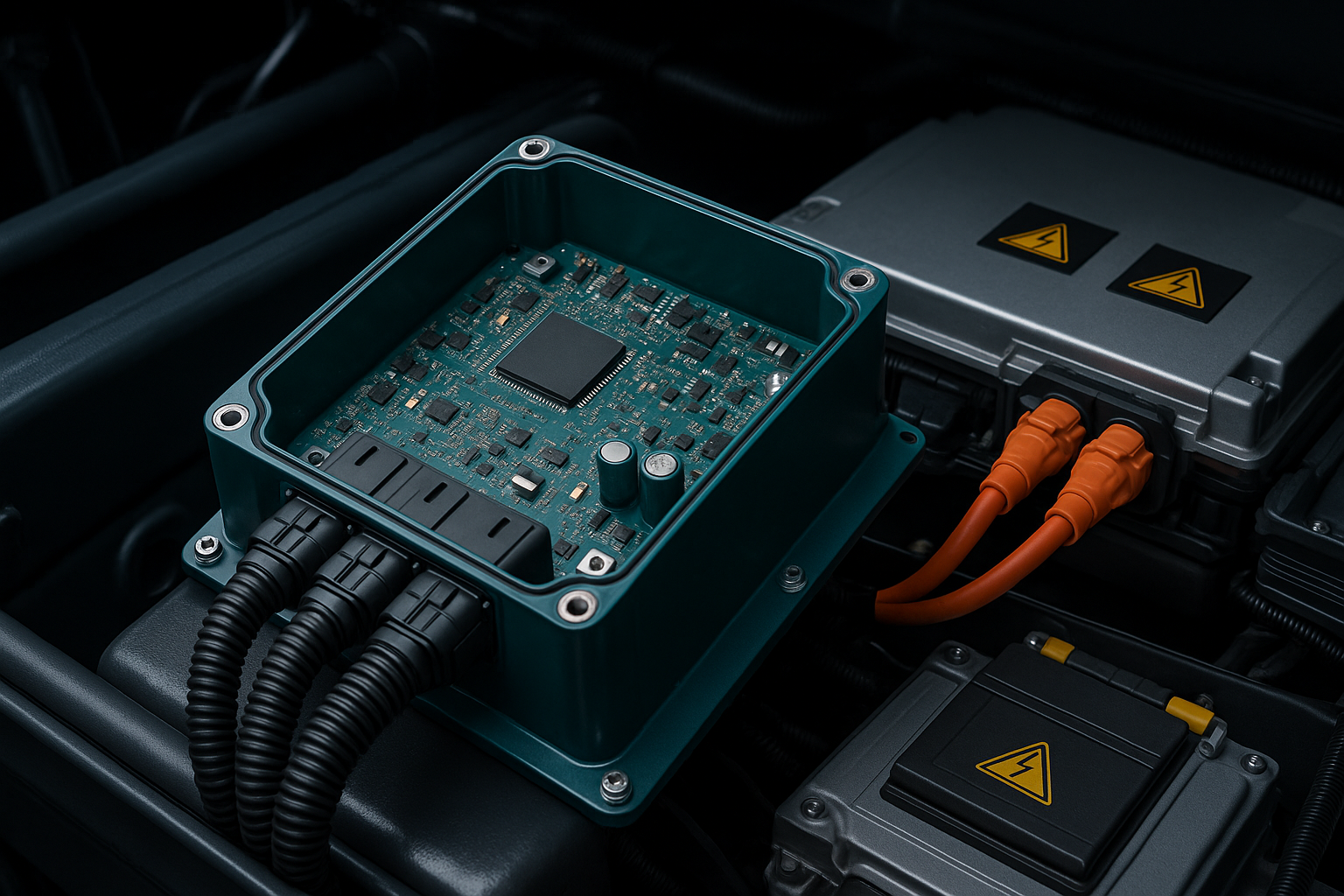

We develop the software for the vehicle control unit of a truck, based on requirements up to ASIL B according to ISO 26262. The functionality includes the coordination of all high-voltage control units and the safe implementation of the torque path. The project is supported by in-house code generators for CAN communication and I/O control tailored to the selected COTS ECU.

We support our customer in safety design, software development, and safety management for an ECU project commissioned by a major automotive OEM. The project complies with ISO 26262 requirements for ASIL B development and also addresses cybersecurity threats as well as ATEX requirements.

Project Archive

Before joining safecubed, the team worked together in several other projects that can only be outlined due to NDAs with previous employers and customers as well:

Chassis control system

We developed the safety concept and the basic software for the utilized ECU with safety goals up to ASIL C. This work included designing and implementing a deterministic software architecture in C, creating a well-integrated development process, and achieving full compliance with the customer’s diagnostic standards. The project’s success culminated in the passing of the safety assessment without any deviations, leading to the installation of our ECUs in a vast number of vehicles.

Electronic braking system

We contributed to the design and implementation of application and basic software for an electronic braking system, utilizing Matlab Simulink and Structured Text. Our collaborative efforts also included enhancing development processes at all stages, which supported the achievement of SIL2 safety integrity. This combined effort culminated in the successful certification of the product.

Basic SW development for COTS ECU

Recognizing the cost constraints of smaller companies, we developed a basic software including a custom RTE, a CAN/COM stack, GPIO abstraction, and a diagnostic stack which enhanced the hardware abstraction of a COTS ECU by STW. Additionally, we implemented a suite of tools to configure the mentioned basic software modules by autogenerating the required configuration files. The tooling provides a graphical user interface which enabled the developers to swiftly adapt the modules to new requirements. In this way, the suite supported the management of multiple vehicle variants simultaneously with a small and efficient team.

SW and system concept for a fuel cell electric truck

We delivered both the system concept and software application for a hydrogen-powered truck’s powertrain, with safety goals reaching ASIL B. The software interconnected all subsystems from various suppliers to ensure reliable and predictable operation, incorporating sophisticated thermal and torque management as per client specifications.

Development of diagnostic tool and integration of diagnostic stack

Our expertise in vehicle diagnostics led to the integration of UDS and J1939 standards into the basic software of vehicle control units. We led the development of a desktop application enabling diagnostic access to both self-developed and supplier-provided control units.

HiL-Testing with Matlab Simulink

We engineered a HiL testing system using Speedgoat realtime hardware and a realtime simulation using Matlab Simulink. Extensive matlab scripting was used to be able to effeciently handle frequent changes in the CAN and GPIO structure. Additionally, a Matlab App allowed the software developers easy access to all needed testing triggers.

Vehicle simulation with Matlab Simulink

Our customer provided multiple vehicle component configurations and his customers required vehicles for very distinct use cases. The team developed a simulation in Matlab Simulink that took the customers track profiles as input and provided the correct choice of motor and battery configuration.